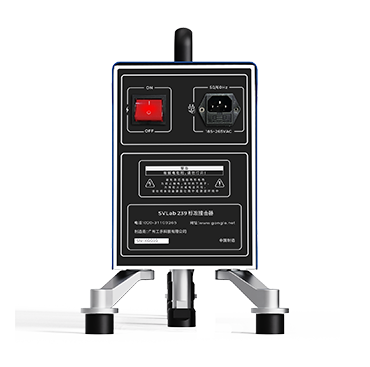

SVLab 239

Lightweight.stable.and professional

Standard Tapping machine

Product name: Standard Tapping machine

Product model: SVLab 239

Manufacturer brand: SVLab

The SVLab 239 standard Tapping machine is a major equipment used for measuring building sound insulation and conducting laboratory research. It is mainly used to measure the sound insulation performance of building floor impacts, providing a stable impact sound source by simulating the sound generated by people walking on the floor or hitting objects.

This standard Tapping machine uses wireless radio frequency technology and can be remotely controlled.

SVLab239 can easily pass through walls and ceilings, and its integrated structural design not only ensures strength, but also achieves lightweight.

This product also supports battery and AC power supply, which can adapt to various measurement scenarios.

Video

Standards

|

|

|

|

|

|

|

Application Scenario

Measurement of floor sound insulation |  Material Sound Absorption Coefficient |  Laboratory Study |

Functional Characteristics

Impact signal stability Adopting a precise mechanical structure and closed-loop control system, ensuring high stability of the impact signal. | Wireless Remote Control Adopting a 433MHz remote control, it has strong wall penetrating ability and a free field remote control distance of over 100 meters. |

Impact Hammer Status Indication Display the status of 5 impact hammers through LED indicator lights to ensure that the impact hammer falls normally. | Temperature control function The standard Tapping machine is equipped with a motor overheat protection function to prevent damage to the motor caused by high temperatures. |

Built in battery powered This product is equipped with an internal battery pack (lithium type), which can help operators work without any cables. The battery automatically charges when connected to the main power supply. A fully charged battery can ensure 3 hours of continuous operation. | Support Manual Operation The standard Tapping machine can not only be remotely controlled through a remote control, but also supports manual control operation through the operation buttons on the front panel of the instrument. |

Technical Specifications

| Impact hammer | 5 hardened stainless steel impact hammers Hammer head diameter 30mm ± 0.2mm Cross zone spacing 100mm ± 3mm Impact surface curvature 500mm ± 100mm Weight is 500g ± 4g |

| Impact frequency | The impact interval between the two hammers is 100 ± 20ms, and the speed is controlled through a closed-loop circuit |

| Impact sequence | 1 #, 3 #, 5 #, 2 #, 4 # (1 # hammer on the input power side) |

| Impact hammer status | Built in drop hammer status and drop speed detection |

| Falling height | 45 mm (± 5 mm adjustable) |

| Supporting foot | 3 folding feet with rubber shock absorbers and adjustable height |

| Remote control | 433MHz, remote control distance>100m (free field environment) |

| Data interface | Lemo connector (supports communication and firmware upgrades) |

| Power supply method | 185-265VAC 50/60Hz AC power supply and nickel hydrogen battery pack power supply |

| Battery capacity | 4000mAh, rechargeable nickel hydrogen battery |

| Battery life | ≥ 4 hour |

| Charging time | ≤ 2 hour |

| Overall power consumption | 16W |

| Overheat protection | Motor overheating protection (90 ℃ protection, 65 ℃ reset) |

| Working temperature | -10 ° to 50 ° C |

| Working humidity | ≤ 90% RH (non condensing) |

| Size | 510*155*292mm |

| Weight | 10.6kg |

Our company's policy is to continuously innovate and develop our products.

Therefore, we reserve the right to change product specifications without prior notice.

中文

中文